Overview

Specification

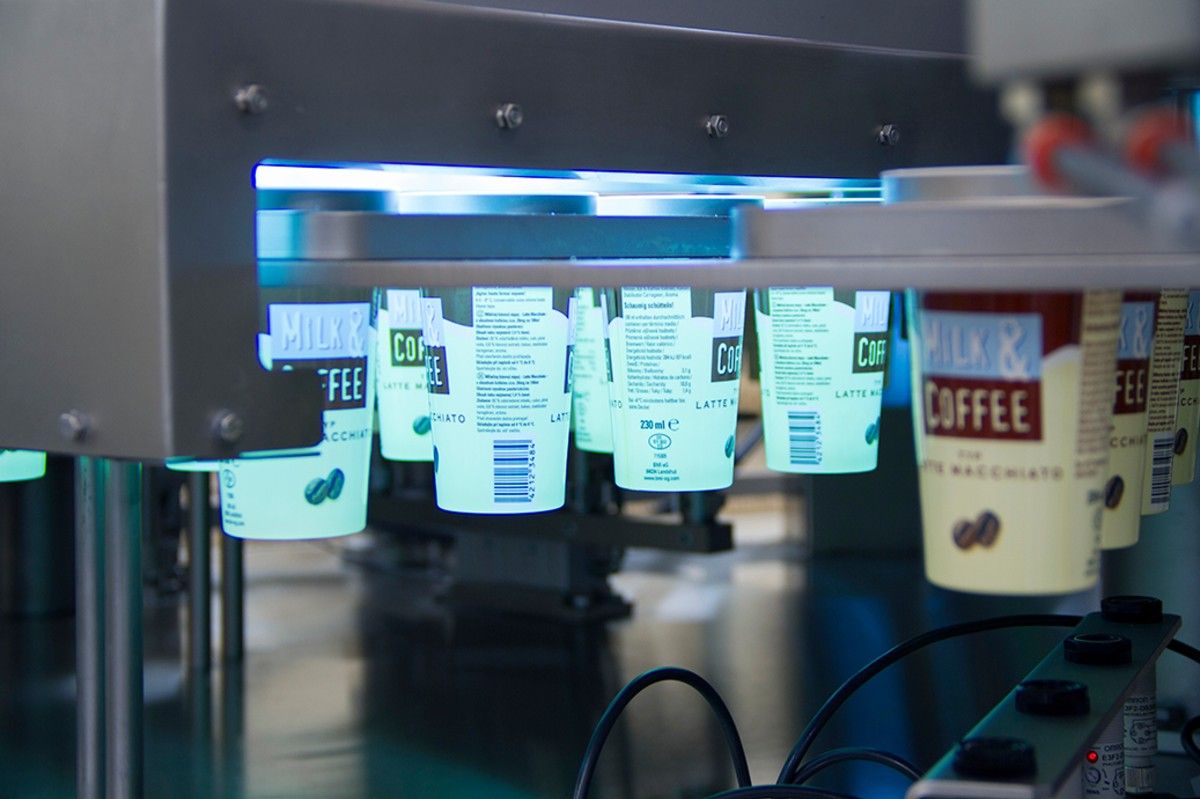

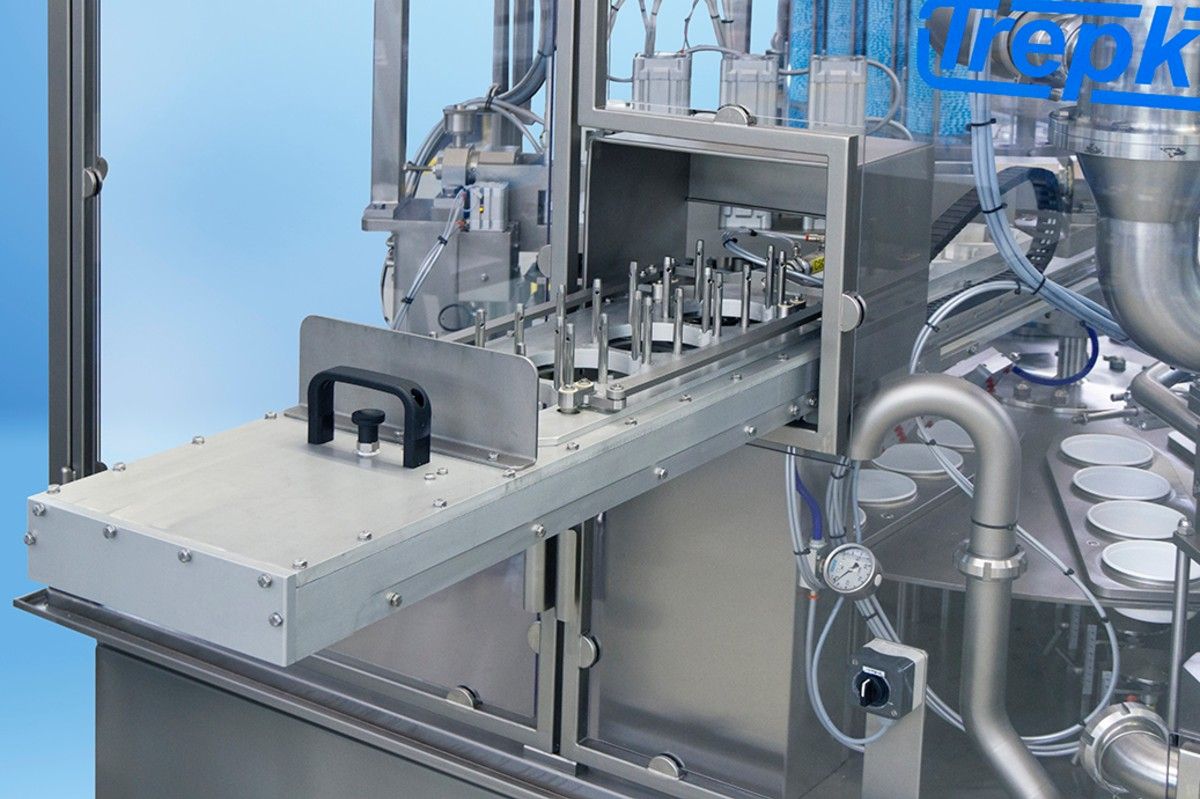

Trepko’s 200 Series provides flexible and effective solutions for the filling and closing of pre-formed containers. The machinery within this range achieves outputs of up to 14,000 cups/hour. Four machine sizes are available (210-220-230-240) dependent on the required output, container size and options required, each with different frame sizes and number of lanes.

Standards

For whom?

Funcionality

Benefits

Flexibility

available for a variety of cups and containers, a variety of products to be filled (desserts with vertical, horizontal and twisted layers, layered dessert with icing, filling cream in an attractive pattern)

Individuality

tailor made solutions

Reliability

modern materials and high quality construction contribute to easy and cheap maintenance, this guarantees the machine’s long life, modern drive systems provide a high standard of packaging

Product safety

during the packaging process the most stringent hygienic standards are maintained, seal check and elimination of defective packaging are available as an option

Comprehensive

integrated solutions for all the phases of the packaging process

Technical data

| 210 Model | 220 Model | 230 Model | 240 Model | |

|---|---|---|---|---|

| Number of lanes (for a Ø 95 mm as example) | 2 | 3 | 4 | 6 |

| Maxmum output (cups/h) | 4.800 | 7.2000 | 9.600 | 14.000 |

| Power supply | 3 x 400 V + PE +N | 3 x 400 V + PE +N | 3 x 400 V + PE +N | 3 x 400 V + PE +N |

| Power consumption | ca. 4,7 kVa | ca. 7,0 kVa | ca. 8,4 kVa | ca. 11,5 kVa |

| Compressed air pressure | 6 bar | 6 bar | 6 bar | 6 bar |

| Compressed air consumption | 36 m3/h | 45 m3/h | 50 m3/h | 60 m3/h |

Machine options

Hygienic

- CIP/SIP of dosers

- sterile air cabin

- vacuum cleaning

- gas flush

- chemical sterilization

- vacuum cleaning

- seal check and elimination of defective cups

- cup deionization

- UV radiation of cup and foils

Efficiency

- stack feeding magazines for cups and lids

- sledge magazine for pre cut foils

- automatic volume adjustment

Dosing and product infeed

- pre- or post dosing

- dry filling

- compensator

- scroll chute hopper

- horizontal or vertical agitators

Applications

yoghurt, cream, kefir, cream cheese, processed cheese, cottage cheese, cottage cheese with fruit pulp, tvorog, quark, fromage frais, desserts, custard, butter, butter with oils, spreads, pâté, luncheon meat, lard, jam, plum jam, marmalade, honey, ketchup, sauces, mousse, puree, conserve, salads, fresh salads, mustard, margarine, mayonnaise

Watch the video and learn more about 200 Series

Do you need more information?

Contact us: info@trepko.com

Check 300 Series

We also encourage you to familiarize yourself with the specification of our cheese packaging and coagulation machines, i.e. our 300 Series.