About Trepko

The Trepko Group is well-recognized globally for providing packing solutions, catering primarily to the food industry while also serving other markets. With a distinguished 75-year history in manufacturing, we have established ourselves as pioneers in the packing sector. Presently, we serve loyal customers in over 100 countries around the world.

Our strategic approach centres on enhancing the quality of our manufactured equipment and services through the utilization of cutting-edge technology and a highly skilled workforce. We are committed to maintaining close collaboration with our customers across various markets, aiming to support their growth and development by providing them with the most innovative solutions available. Our primary objective is to surpass competitors, ensuring our position as a leading force in the ever-evolving landscape of the packing industry.

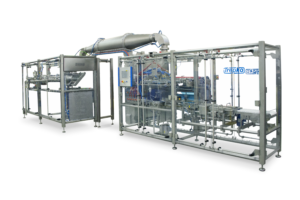

Moreover, Trepko stands as the only company in the world providing complete in-house manufactured perfectly integrated lines starting from the intake of raw ingredients all the way through to packaging the final product and placing it on the pallet ready to go to the distribution center. This unique capability entails not only one-stop shopping but also, and more importantly, one-stop service. It simplifies training and operation while significantly reducing the requirements for stocking spare and wear parts. This integrated approach underscores our dedication to seamless efficiency and unparalleled customer satisfaction.

The significant international successes we have achieved across global markets validate our trajectory as a company. With a robust presence in Europe, North and South America, the Middle East, Africa, and Australia, we have firmly established ourselves as a leader among packaging machine manufacturers. The unwavering growth and success of Trepko underscore our commitment to excellence and solidify our reputation as a trusted industry leader worldwide.

Trepko’s machines adhere to the most rigorous standards of quality and hygiene, ensuring compliance with stringent requirements. Their exceptional performance, coupled with their inherent flexibility, enables us to deliver tailor-made and optimized solutions that precisely cater to our customers’ unique needs. We employ the latest advancements in technical and technological solutions, utilizing certified components throughout.

The majority of Trepko’s production is meticulously carried out in-house, further reinforcing our commitment to ensuring uncompromising quality and timely delivery. By maintaining control over the entire manufacturing process, we can closely monitor and uphold our rigorous standards at every step. This in-house approach allows us to have a comprehensive understanding of the production timeline, enabling us to consistently meet delivery deadlines without compromising on quality.

75 years of manufacturing

120

countries

wide

offer

team of

specialists

Trepko History

1947

The company was founded by Mr. Poul Petersen, who started out the company working together with an old friend also with the name Petersen. Thereby the name became “Trepko” meaning three P’s in company. After a few years, Mr. Petersen retired from the company leaving Mr. Poul Petersen as the sole owner.

The first factory was situated in the center of Copenhagen: Steen Winkelsvej 6, Frederiksberg. The factory with the phone number „LUNA 1056” consisted of a office containing 3 small rooms, and a workshop around the corner with 7 workers. The office housed for many years a part-time secretary, a part time engineer, as well as the founder and his son, who were both engineers.

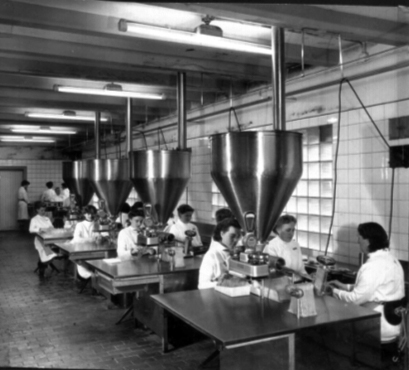

The first types of filling machines were constructed for the filling of marmalade. Later machines were developed for the filling of mayonnaise based salads, including a closing system for the application of plastic lids to plastic cup.

1962 – 1964

1962

The company moves out of its original premises and into a newly built tailor-made factory at Rugvanget in Taastrup (just outside Copenhagen).

1964

A new filling machine for the filling of yoghurt into plastic cups was developed. In Denmark it was now allowed to add fruit to yoghurt and consequently the market for fruit yoghurt boomed, and Trepko supplied the required filling machines to the many local dairies in Denmark. The filling machines soon became known as sturdy and effective machines, which proved them ideal for export. During the following years export to overseas countries in the middle east and practically all over the world picked up

1972

Prior to the Olympic Games in Moscow there was a great interest in the production of Cottage Cheese for the sportsmen and the visitors to the games. This came to be the start of a large order for fillers for Cottage Cheese – not only to dairies in Moscow but also in the large Russian towns along the Trans Siberian railway. The order forced the company to expand the factory to include a larger factory at Kuldyssen 15 in Taastrup.

Picture of the workshop full of machines under construction for the USSR.

1975 – 1996

1975

Technically Trepko had some interesting years. The machines were developed to handle many new products – for instance margarine and butter – products that required a system with continuous feeding of the product through a compensator.

As the Danish dairies were merging, capacity requirements rose, whereby the capacity of the machines was increased. The filling/closing machines were thereby now supplied with up to 8 parallel lanes. These machines were not only of interest to the large Danish dairies, but also increasingly interesting to the large international food companies around the world.

1996

Mr. Henning Poul Holskov who has taken over the company after his father (the founder) retires at the age of 62, and sells the company to Mr. Hans Christian Hansen (the present owner).

Group picture from the entrance to TREPKO’s reception (approx. year 1990) . From left to right: Henning Holskov (the former manager and owner), Gudrun Petersen (Henning Holskovs mother), Alice Hansen (accountant assistant), Hanne Herager (Chief accountant), Karin Hartman (Secretary), Lisbeth Holskov (Sales secretary and wife of Henning Holskov).

2000 – 2002

2000

The majority of shares in Unipak Sp.z.o.o. in Poland is bought. Unipak Sp.z o.o. is the largest and technologically leading supplier of filling and closing machines in Central and East Europe. The name is changed to Trepko Sp. z o.o. The production of machined components is moved from the factory in Taastrup to the new company.

2001

A new – more modern – logo is adopted.

2002

A sales office is opened up in Egypt. The office serves the Middle East and North Africa.

2006 – 2008

2006

Regal Ltd. the leading producer of filling/closing machines in the United Kingdom is acquired. The name is changed to TREPKO Ltd.The decision to gather the production of in-line filling machines in TREPKO UK is undertaken

2008

Meco Pak Ab Scandinavia’s leading supplier of end-packaging machines is acquired. The name is changed to TREPKO AB.

2009 – 2012

2013 – 2014

2013

Trepko launched its series of 9100 Form, Fill Seal Machines. The series cater for high capacities, large portion packs and employ in-mold labeling. The technology was first unveiled at the 3rd Trepko Conference and Exhibition.

2014

Hugart of Poland was acquired and joined the Trepko Group becoming Trepko’s new center for development of Ultra-Clean and Aseptic machines. Hugart changed its name to Trepko Aseptic Sp. z.o.o. and new logo was introduced.

Trepko UK opened the 800 square metre factory extension located on the side of the existing assembly hall. It is utilised as a dedicated machining centre for parts manufacturing. Trepko UK acquired a precision machined components producer, KDR Engineering. KDR Engineering was fully integrated with Trepko UK. The new machining centre was equipped with 30 production machines.

The implementation of the third generation of 822 Brick Forming and Wrapping machines with an 8 drive system and new mechanical solutions to achieve a capacity of 260 bricks/min

2015 – 2016

2015

Trepko launched its Aseptic technology, unveiling it at Anuga Food Tech on a In-Line Cup Filling and Packing Machine.

Filmatic joined the Trepko Group. Hereby the Trepko product portfolio was further strengthened by the inclusion of high-capacity Ultra Clean Bottle Filling lines. Trepko established itself as the ONLY one-stop automation supplier for food manufacturers.

Brasholanda is the leading producer of the cup- filling and closing machines in South America. Brasholanda Joined the Trepko Group which is known as Trepko Brazil. Trepko Brazil employs 50 employees, and has proved capable of achieving an impressive increase in its turnover during the past 5 years. Trepko Brazil has continued its product-lines but also started functioning as Trepko’s local manufacturing site. Trepko Brazil provides easy access to after sales services to Trepko existing customers in South Amercia.

2018 – 2019

2018

Trepko moves into the bulk filling industry by launching its 600 Series consisting of Bag in Box filling lines. This was the first machine type developed for Trepko’s new Bulk-filler programme. The technology was first unveiled at the Pax Expo Fair in Chicago on October 14—17, 2018

2019

2019

Continuation of the Bulk-Filler programme.

During the 5th Conference & Exhibition , Trepko presented the new Trepko’s Bulk Filling, Forming & Wrapping machines – 850 Series.

2020 – 2022

Trepko made a significant leap by venturing into the processing solutions field, expanding its product range to include homogenizing and butter cutting machines.

This strategic expansion signified Trepko’s commitment to providing comprehensive solutions and catering to the evolving needs of its customers. The integration of the Trepko 860 Homogenizer with the Trepko 861 Block Chopper, the Trepko 800 Brick Wrappers, and the Trepko 100 & 200 Cup fillers was seamlessly executed, ensuring compatibility and enhancing efficiency across the entire production line.

2023

Trepko achieved worldwide recognition in aseptic packing excellence.

As the first company to introduce Aseptic Rotary Cup Filling Machinery to the market, Trepko set a new standard for excellence and reliability. Its innovative solutions have empowered businesses across the globe to embrace aseptic packaging, extending product shelf life and ensuring uncompromised quality. From TREPKO’s pioneering space-saving design to its unparalleled log 5.9 decontamination level and energy-saving features, Trepko’s machinery has become the preferred choice for companies seeking the highest standards of hygiene, efficiency, and sustainability. The full potential of aseptic packing has been unlocked.

2024

A new generation of ultra high-speed butter and margarine brick wrappers are introduced with the Series 822UHS.

2025

Trepko acquires the entire product offering of Egli AG Processing Technology, expanding Trepko’s portfolio to include butter and margarine processing equipment, making Trepko a true one-stop shop for the global dairy and fats and oil industry.

See our offer

We encourage you to familiarize yourself with the offer of Trepko packaging machines