Overview

Discover the Future of Aseptic Technology by Trepko

In response to the escalating demands of consumers for extended shelf life of sensitive products, without compromising on quality by using preservatives;

Trepko proudly presents our In-Line Aseptic Technology Packaging Machine. We understand the challenges faced by the food industry, and our solution is tailored to revolutionize your packaging process while ensuring maximum safety and prolonged freshness.

Standards

As standard and as with the entire range of Trepko machines, the 100 Series is CE– marked and is built in accordance with all applicable European safety standards.

Years of Aseptic Excellence

With a rich legacy of experience spanning numerous years in the aseptic sector, Trepko stands as a testament to unwavering dedication and expertise. Our team has continually pushed the boundaries of innovation to develop aseptic solutions that cater to the evolving needs of the industry.

Benefits

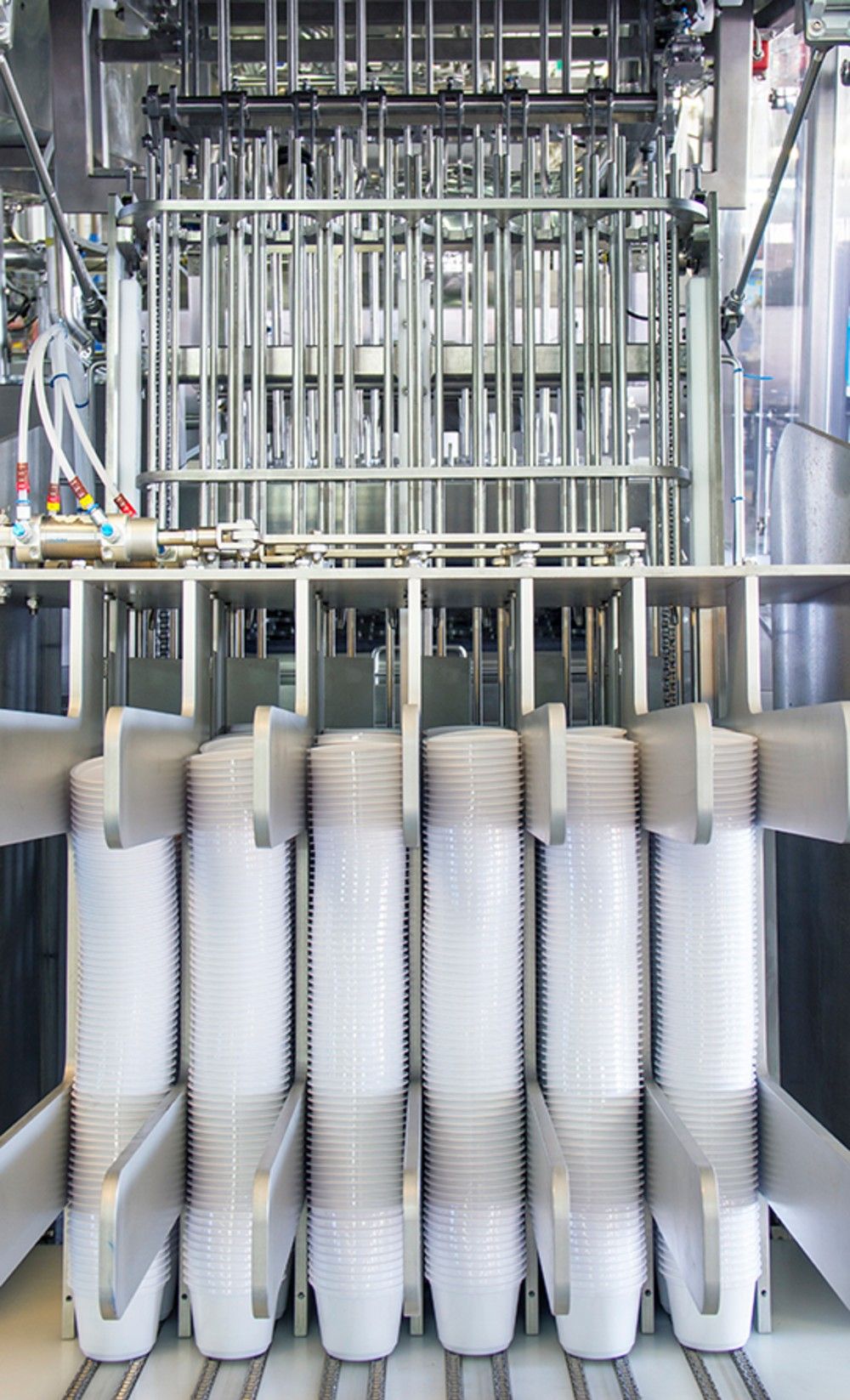

Flexibility

suitable for a variety of products, available for both cups and straight sided containers, quick size change, flexibility in design, multiple index options for different cup sizes

Versatility

modular design to allow for customer bespoke layouts, manufacture and operation

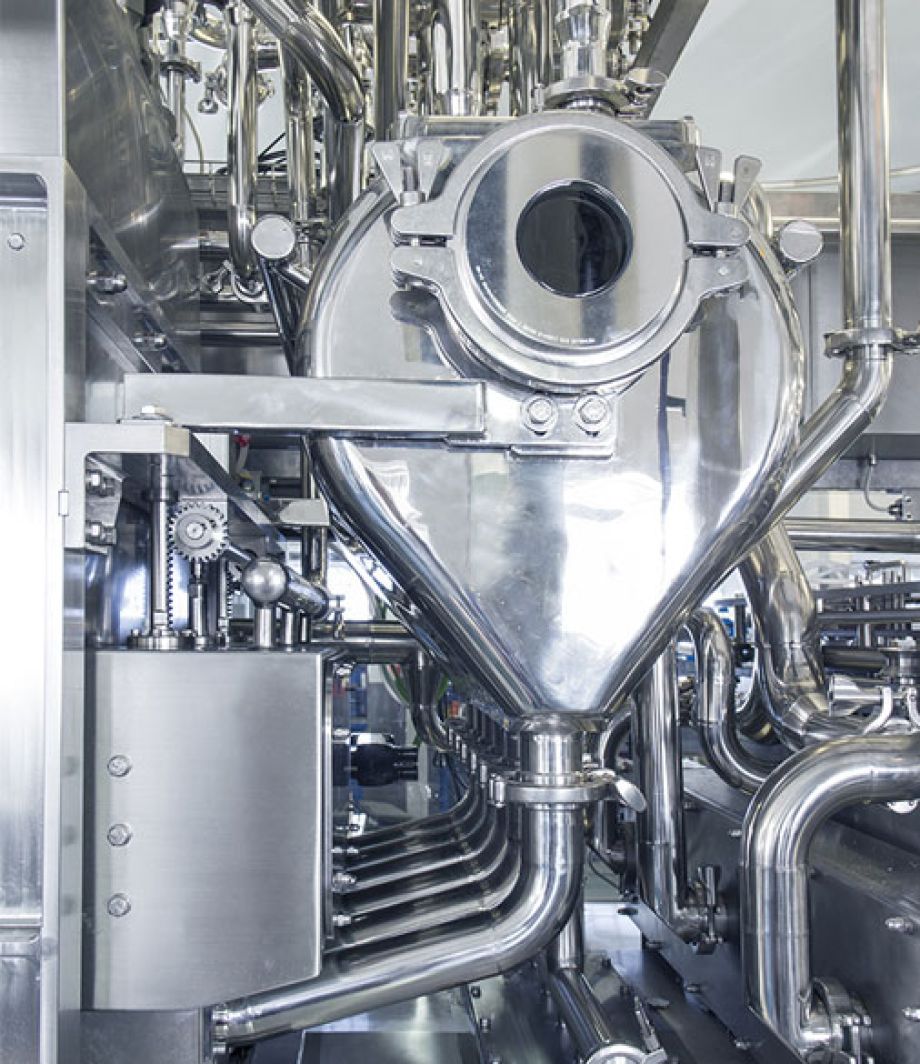

Comprehensive

integrated solutions for all the phases of the packaging process

Individuality

tailor made solution

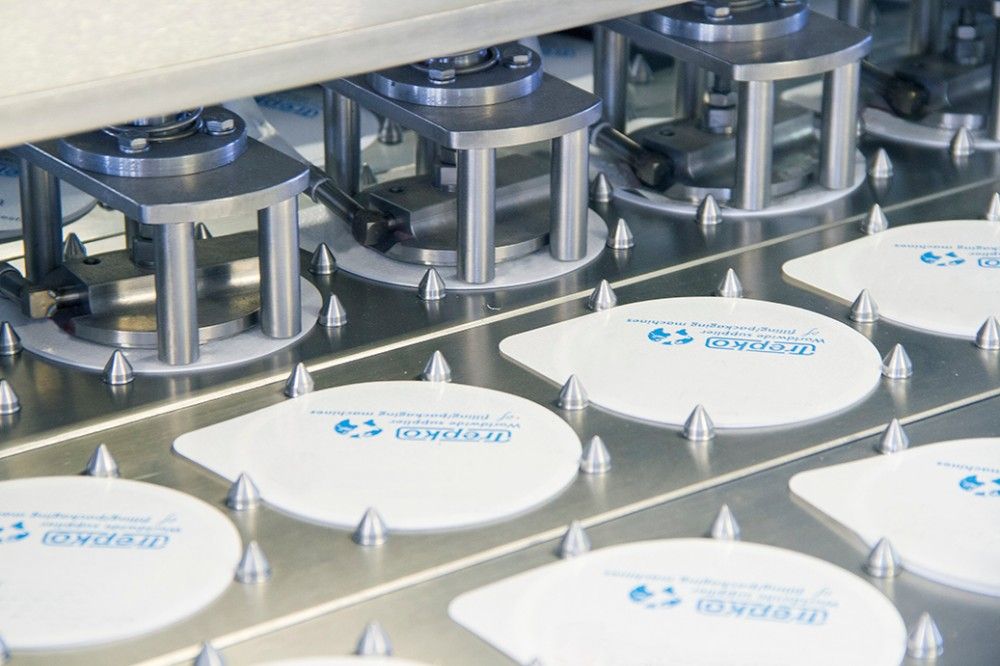

Hygiene

three levels of hygiene: Aseptic, Ultra Clean, Standard,

Technical data

| Number of filler points | Dependent on customer requirements |

| Number of lanes | Dependent on customer requirements. Standard range comprises of 1,2,3,4,6,8 and 10 lanes, single or double index |

| Maxmum output (cups/h) | Dependent on number of lanes and product being filled |

| Max. cup dimensions (mm) | Up to 200 mm dia |

| Max. cup height (mm) | Up to 130 mm |

| Power supply | Dependent on machine configuration, typically 415V, 3 Ph + O + E, 50 Hz |

| Power consumption | 16 amp supply |

| Compresed air pressure | 7 Bar Clean Dry Air |

| Compresed air consumption | Dependent on machine configuration |

Machine options

Efficiency

- stack feeding magazines for cups and lids

- sledge magazine for foil lids

- automatic volume adjustment

- automatic weight adjustment

Applications:

Watch the video and learn more about 100 Series

Do you need more information?

Contact us: info@trepko.com

Check our 200 Series

We also encourage you to familiarize yourself with the specification of 200 Series