About Us

The Trepko Group is well-recognized globally for providing packing solutions, catering primarily to the food industry while also serving other markets. With a distinguished 75-year history in manufacturing, we have established ourselves as pioneers in the packing sector. Presently, we serve loyal customers in over 100 countries around the world.

Our strategic approach centres on enhancing the quality of our manufactured equipment and services through the utilization of cutting-edge technology and a highly skilled workforce. We are committed to maintaining close collaboration with our customers across various markets, aiming to support their growth and development by providing them with the most innovative solutions available. Our primary objective is to surpass competitors, ensuring our position as a leading force in the ever-evolving landscape of the packing industry.

Moreover, Trepko stands as the only company in the world providing complete in-house manufactured perfectly integrated lines starting from the intake of raw ingredients all the way through to packaging the final product and placing it on the pallet ready to go to the distribution center. This unique capability entails not only one-stop shopping but also, and more importantly, one-stop service. It simplifies training and operation while significantly reducing the requirements for stocking spare and wear parts. This integrated approach underscores our dedication to seamless efficiency and unparalleled customer satisfaction.

The significant international successes we have achieved across global markets validate our trajectory as a company. With a robust presence in Europe, North and South America, the Middle East, Africa, and Australia, we have firmly established ourselves as a leader among packaging machine manufacturers. The unwavering growth and success of Trepko underscore our commitment to excellence and solidify our reputation as a trusted industry leader worldwide.

Trepko’s machines adhere to the most rigorous standards of quality and hygiene, ensuring compliance with stringent requirements. Their exceptional performance, coupled with their inherent flexibility, enables us to deliver tailor-made and optimized solutions that precisely cater to our customers’ unique needs. We employ the latest advancements in technical and technological solutions, utilizing certified components throughout.

The majority of Trepko’s production is meticulously carried out in-house, further reinforcing our commitment to ensuring uncompromising quality and timely delivery. By maintaining control over the entire manufacturing process, we can closely monitor and uphold our rigorous standards at every step. This in-house approach allows us to have a comprehensive understanding of the production timeline, enabling us to consistently meet delivery deadlines without compromising on quality.

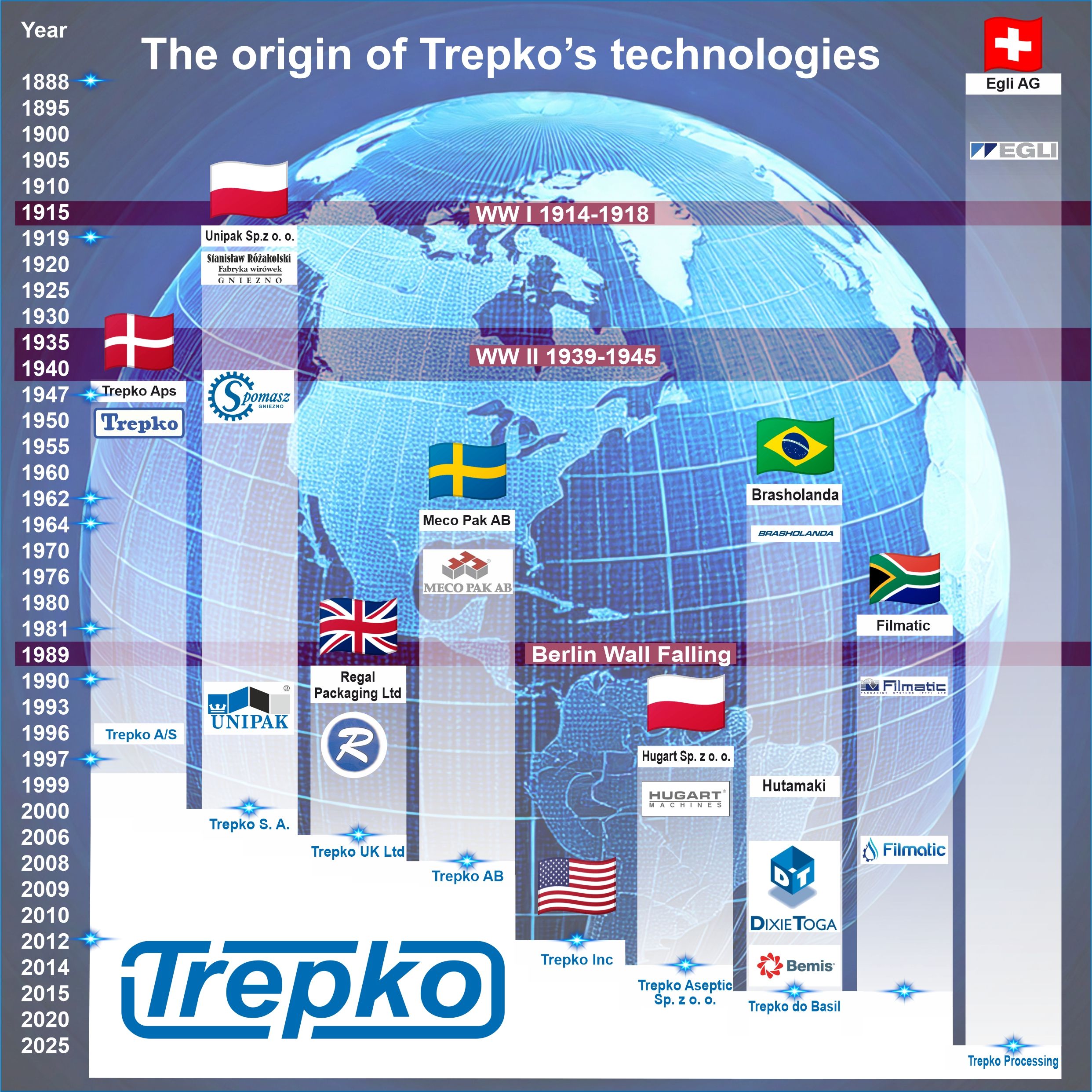

Trepko History

1888-2025 So many stories to be told

The story of Trepko is a tale of clever engineers with passion. People outside the industry may find it challenging to understand the emotions machine builders associate with their products and companies. Still, if one is genuine about getting a feel for it, one may criticize their creations and gauge their reaction. What may be overlooked, and what sets Trepko apart from many of its peers, is that it is also a tale of economists.

Machine-building companies tend to be fully engineer-driven, with little attention to the company’s financial well-being. This was also the situation in Trepko until 1996 when an economist purchased the company and focused on costs, product optimizations, logistics, and more.

In Trepko, these cultures did not clash; they embraced each other and paved the way for a truly unique company that would eventually form an international group of fully integrated companies aimed at building food factories throughout the world.

Trepkos’ self-made wealth enabled it to purchase strategic partners and technologies worldwide and join them into a powerful constellation, capable of developing products, doing projects, and solving tasks that none of the companies would ever have been able to master individually. Trepkos’ history also becomes a tale of many different nationalities working together, fired up by the joint passion for a mutual mission.

It’s fascinating that Trepko’s history has come to engulf a man in Switzerland building butter churns from wood before the turn of the 19th century and a man in Poland repairing cream separators as World War 1 draws to a close, as well as two Dutchmen going to Brazil and starting packaging manufacturing in 1960 when plastic for use in packaging had only just started to take off, and that a man in Sweden at the same time decided to start a company for something as – at the time – visionary as end of line packaging machines.

These and thousands of other passionate people are those on whose shoulders we stand.

1947-1961 A new era & a new company

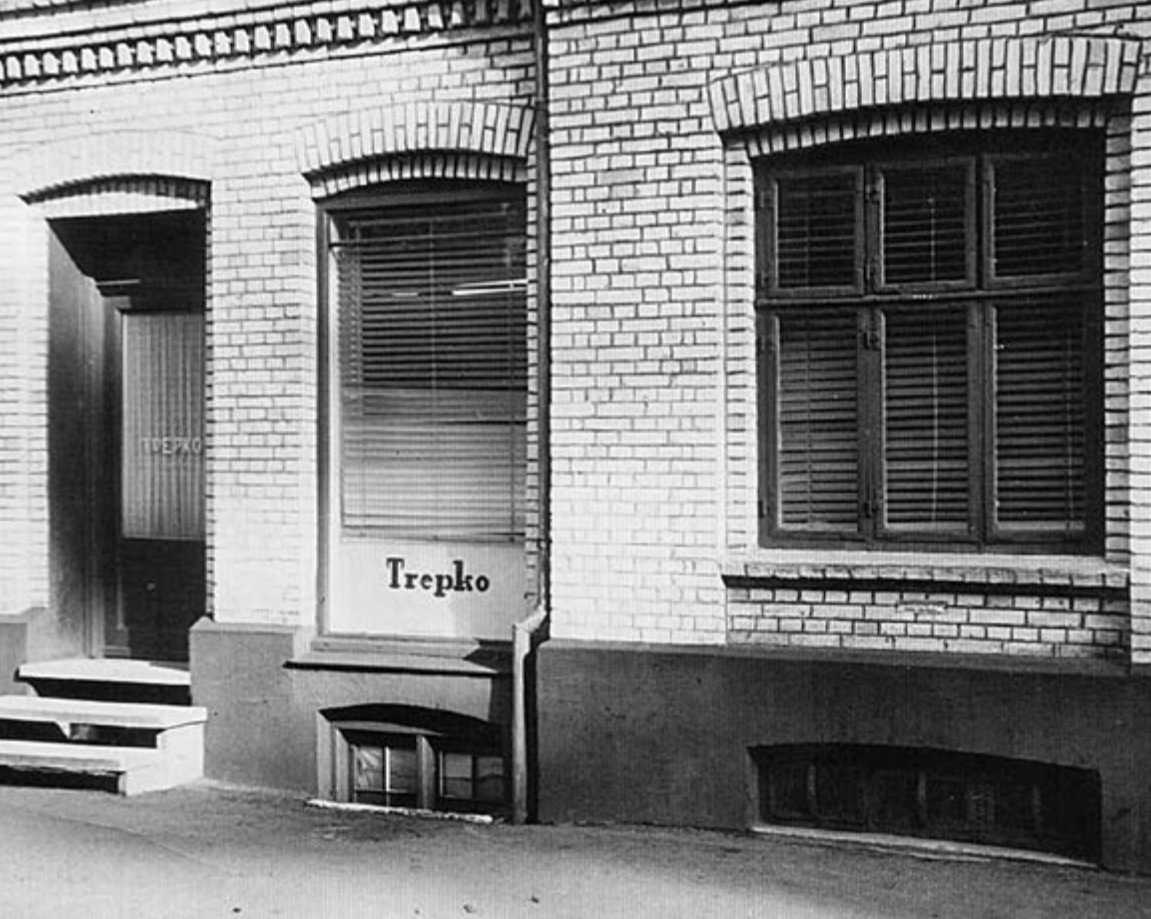

In 1947, only a year after the final withdrawal of enemy forces from Denmark, the engineer Poul Petersen founded a tiny machine shop with an old friend sharing his family name. Slightly pretentious, they named the company “Trepko” meaning Three P’s in company.

From the very outset, the small entrepreneurial company manufactured filling machines. The original focus was on marmalade filling, but with little tweaks, the designs soon proved applicable to other food industries, such as mayonnaise. Gradually, container closing and other functions were added, increasing the degree of automation.

Trepkos first ”factory” was situated in the center of Copenhagen on Steen Winkelsvej 6, Frederiksberg. The factory with the phone number „LUNA 1056” consisted of an office containing 3 small rooms, and a workshop around the corner

While Poul Petersen’s friend retired from the company at a very early stage, the company grew in its humble domicile, where it employed seven workers, a part-time engineer, and a part-time secretary, apart from the founder and his son Henning Holskov, who was also an engineer.

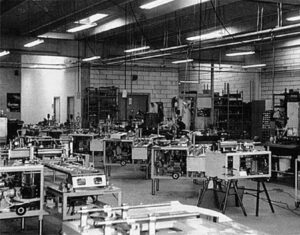

A factory fully equipped with an early version of Trepkos semi-automatic filling machine, the type 620, which, with only a few modifications, remained in production up until the turn of the century. With only very few models, the three-digit model number helped maintain an image of a nonexistent product line. On the other hand, it could also be argued that the founder was a visionary, as Trepko continues to use the same system today and has significantly expanded on it!

1962-1974 The Danish Youghurt Boom opens up the world!

Already in 1918, Danish dairies started experimenting with adding taste to yogurt. Still, only 7 years later, a law was passed, ending this “insanity,” thereby also putting a damper on yogurt consumption.

The product was commercially reviewed again by many Danish dairies in 1958, and the product performed successfully with steadily growing sales volumes up until 1964 when milk consumption, in general, had declined in Danish households. At this point, the ban on adding flavors to yogurt was revoked to offset the decline, and a yogurt revolution took place! The local dairies’ demand for increased yogurt capacity and productivity grew, as did Trepko’s demand.

In 1962 groving demand from yogurt manufacturers caused the company moved out of its original premises and into a brandnew tailormade factory at Rugvænget in Tastrup (just outside Copenhagen).

In perfect parallel with the Danish yogurt boom, plastic entered the global packaging segment. In 1964, Trepko responded with its first in-line filling machine for the filling and closing of yogurt in plastic cups.

These filling machines soon became known as sturdy and effective machines, which proved them ideal for export. In the following years, the world opened up to Trepko, with especially the middle east proving to be an attractive export market.

Prior to the Olympic Games in Moscow there was a great interest in the production of cottage cheese for the athletes and the visitors to the games. In 1972 this came to be the start of a large order for fillers for

cottage cheese – not only for dairies in Moscow but also for large Russian towns along the Trans Siberian railway.

The order resulting from the Olympic Games forced the company to expand the factory to include a larger factory at Kuldyssen 15 in Taastrup (200 meters down the road from the main factory). Here, the popular in-line cup fillers are being assembled.

1975-1996 Higher Capacities, Margarine & Butter!

In the 1880’s, dairy cooperatives started to take form in Denmark. By the farmers joining forces, investment in machinery, buildings and eventually research was enabled, causing manufacturing productivity and product quality to rise. From 1950 up to 1999, consolidation took place reducing the number of dairies from hundreds to one large and a handful small.

Being the first country in the world to form dairy cooperatives, Danish industry obtained a head-start within dairy technology. The cooperatives had growing demand and investment power, which the local farm dairies could never even begin to imagine and which local machine producers scrambled to satisfy.

As the dairies in Denmark merged, capacity requirements rose and the capacity of the machines increased. The filling/closing machines were now supplied with up to 8 parallel lanes. These machines were not only of interest to the large Danish dairies, but also increasingly interesting to the large international food companies around the world.

From 1975 and throughout the next 20 years Trepko adapted the existing designs to many new products. Some of the more demanding products were butter and margarine, which required a system capable of handling continuous product feeding. For this use, the company developed a compensator.

An informal but close cooperation with the processing company Gerstenberg & Agger assisted in the sale of margarine filling machines all over the world. Butter and margarine would prove to be products that would significantly shape the direction of the company.

During these years, the company built up solid positions in somewhat random parts of the world. For example Henning Poul Holskov (the son of the founder) had found himself a girlfriend in the U.S.A. At that time the route from Denmark to the U.S.A. would go over Iceland where the plane would stop to fuel. With his frequent visits, Henning Holskov would exploit these stopovers to exhaust the local dairies with his many frequent visits.Being the only machine manufacturer to regularly visit the remote country, Henning Holskov’s love catapulted into Trepko being the preferred brand of filling machines operating in Icelandic dairies – a status the company still maintains to this day!

In 1996, Mr. Henning Poul Holskov retires at the age of 62, and sells the company to the family of Mr. Hans Christian Hansen (the present owners).

Group picture from the entrance to TREPKO’s reception (approx. year 1990) . From left to right: Henning Holskov (the former manager and owner), Gudrun Petersen (Henning Holskovs mother), Alice Hansen (accountant assistant), Hanne Herager (Chief accountant), Karin Hartman (Secretary), Lisbeth Holskov (Sales secretary and wife of Henning Holskov).

1996-2001 A new course is set

In 1996, Hans Christian Hansen buys Trepko from the retiring owner and a new course is set for the company. A focus is put on driving down cost, while maintaining and improving quality.

A key driver was in-sourcing, which was much against the fashion of the time. While Trepko had primarily been a factory performing design and assembly, the manufacturing of the machine components was now being in-sourced. For a small factory, this required heavy investments; the factory building was expanded and the workforce over the coming years grew from just under 40 to over 70 employees.

The in-house manufacturing enabled more streamlined designs and thorough quality control and traceability. Even today, the philosophy remains an important part of Trepko’s DNA, and it is adopted by all Trepko’s factories worldwide.

Another critical strategy coming with the new ownership was a targeted increase in production capacity and a horizontal expansion of the product line. This led to the acquisition of Unipak Sp.z.o.o. of Poland in the year 2000. This was the largest and technologically leading supplier of filling and closing machines in Central and East Europe.

Another critical strategy coming with the new ownership was a targeted increase in production capacity and a horizontal expansion of the product line. This led to the acquisition of Unipak Sp.z.o.o. of Poland in the year 2000. This was the largest and technologically leading supplier of filling and closing machines in Central and East Europe.

The new company, Unipak Sp.z.o.o., was specialized in low to medium capacity rotary cup-fillers (now Trepko’s 200-series) , which was a perfect supplement to the high capacity in-line cup-fillers Trepko was already specialized in. In addition the new company had a large production of brick wrappers (now Trepko’s 800-series) for butter and margarine, which they even supplied to other manufacturers, such as Benhil of Germany.

2002-2007 Investing in products and manufacturing

With the acquisition of Unipak, the breadth of Trepko’s product-line, started to move in the direction of Trepko being able to serve dairies and margarine factories with the majority of their filling/closing needs. Organic growth of the product offering continued and considerable resources were poured into improving the increasingly popular 200- and 800-series, targeting a market leader position.

In 2006, Trepko took another step towards solidifying its market position within filling/closing machines. This time, the company acquired Regal Ltd., the leading producer of filling/closing machines in the United Kingdom. With Regal’s product line, a multitude of technologies for dessert filling added to Trepko’s already expansive product offering.

In 2002, the company took its first step towards processing, with its 300 series for packaging and coagulation of U.F. white cheese (“cast feta”).

Regals factory (Gainsborough, England) in 2006 displaying both Trepkos and Regals logo. 8 years later Trepko UK acquired a precision machined components producer, KDR Engineering, which became fully integrated with Trepko UK. This required a heavy expansion of the factory that would host a new machining area equipped with 30 production machines.

The philosophy of ensuring quality through in-house production required heavy investments in this period, especially at the new site in Poland where the component manufacturing was now centered. The workshop was modernized with the purchase of CNC-machines, water-jets and the implementation of a modern production management system ERP/MRP.

2008-2011 The idea of a “One Stop Shop”

Seeing the complications customers experienced when putting up manufacturing lines, Trepko realized that integrating multiple manufacturers’ equipment into one line was more often problematic than not. It was almost impossible for customers to foresee if the equipment they bought was compatible and how it would interact when installed.

A company capable of handling the entire product line stretching from where the product left the piping until it was ready on the pallet would truly position itself as a unique supplier and solution provider – a problem solver!

Moreover, a complete line built on the same design platform, employing the same standards and components, would reduce the service cost and the required spare parts stock-hold. Another advantage that could be obtained this way was the line being controlled as one machine through one interface, making data collection easier and operation smoother.

In 2008, these thoughts led to the acquisition of Meco Pak AB of Sweden. Meco Pak had a rich history within end-of-line equipment and had, as a supplier to TetraPak, had its focus on the food industry, especially dairy.

With the acquisition of Meco Pak, Trepko could now offer complete filling/packaging lines as the product portfolio was expanded by wrap-around cartoning machines, tray erectors, shrink-tunnels, conveyors, and palletizers.

For Trepko, a milestone was accomplished by including all the downstream equipment in the product offering. Still, the question of including upstream equipment in the processing would soon arise. This could enable Trepko to supply entire factories …

The acquisition of Meco Pak AB of Sweden fulfilled a stra-tegic ambition as it enabled Trepko to be the only machine manufacturer within its field to supply complete in-house bild filling/packing-lines.

An early version of Trepko’s Wrap-around based on Meco Pak’s design. This machine type became very popular and is now known as the

710-series.

2012-2015 Creating an international platform

The next four years were exciting times. In 2012, Trepko established its operating center, Trepko Inc., in the United States. The center’s purpose was to cater to North- and Central America.

Trepko Inc, moved into its new premises in Tampa, Florida in 2012. In 2018 Trepko Inc bought a 14,000 sqft facility, 2 miles up the road.

Only 3 years later, Trepko continued its expansion in the Americas, as it purchased the leading producer of cup-filling and closing machines in South America: Brasholanda. Brasholanda also contributed to the Trepko product line with high-speed wrap-around machines.

Brasholandas factory in Curitiba, Brazil, in 2015 when the company joined Trepko. The factory was expanded in 2024, as the company in-sourced component-manufacturing, which is in line with Trepkos philosophy.

Also, in 2015, Trepko bought the majority share in the South African company Filmatic. Filmatic was an excellent fit for Trepko, as the company was the leading manufacturer of bottle-filling lines on the African continent. Therefore, Filmatic was an important piece of the puzzle, widening Trepko’s product range and creating a global foot – print for manufacturing and service.

Filmatics factory in Paarl (outside Cape Town, South Africa) at the time of the company joining Trepko. In 2024 the company build a brand new factory that was tailor-made for its purpose.

In 2014, Trepko bought the Polish Cup-filling machine manufacturer Hugart (Now “Trepko Aseptic”). The company was building up a position within very advanced Ultra Clean machines. As the company joined Trepko emphasis was put on developing an Aseptic In-line-cup-filling machine; the 100A-series, which the company launched at Anuga FoodTec already the following year.

2016-2024 Solidifying the product range

The time had come to take a break from growing the group by buying companies. The focus shifted to integrating and developing the companies that had joined the group, ergonomic growth of the product portfolio, and improving products to achieve a market leader status within each product group.

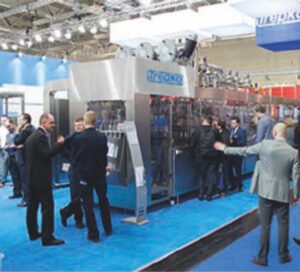

At the 2018 Pack Expo in Chicago, Trepko launched its first bag-in-box filling machines for the butter and margarine industry. While based on traditional concepts for such machines, the lines stood out due to their hygienic level. Trepko took this to the next level 5 years later when presenting a mono-block laminar-flow version of the machine at Interpack in Dusseldorf in 2023. With this, Trepko set a new standard for the industry.

Also at Interpack in Dusseldorf, Trepko presented the world’s first Aseptic rotary cup filler. LOG-reduction results verified by the Fraunhofer Institute documented the remarkable efficiency of the machine.

The world’s first aseptic rotary cup filler (the 200A series) is on display at Interpack 2023. The machine offers an attractive alternative to existing aseptic technologies with its extreme flexibility, compact shape, and competitive price point.

Trepko were triumphant as it showed off its new product launches at Interpack 2023. Here the mono block bag in box filler is on display.

In the autumn of 2024, Trepko launched the 800UHS series, which was the fourth generation of Trepko’s popular brick wrappers typically used for brick forming and paper wrapping of butter and margarine. This new generation consisted of a series of Ultra High Speed Brick Wrappers that achieved a lower wear and 40% increased operation speeds, positioning Trepko at the absolute forefront of the industry.

2025… A dream comes to fruition

With a giant leap, Trepko in 2025 made its final step towards enabling the supply of complete factories, as it acquired the product line of Egli AG Process Technology of Switzerland, thereby creating “Trepko processing.”

Dating back to 1888, Egli is the world’s largest supplier of butter processing equipment and has a complete product offering aimed at the Margarine industry.

By Trepko including both the upstream and the downstream equipment in its filling lines, many unknowns are removed from the equation, reducing the duration of commissioning and increasing the likelihood of a successful project.

With this acquisition, Trepko’s almost 20-year-old dream has come to fruition, but the target is now aimed at increasing its processing capabilities, allowing Trepko to cater to even more industries …

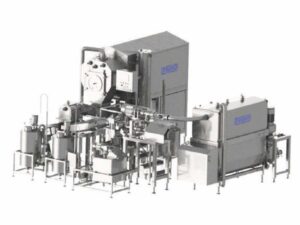

Trepkos Margarine Pilot set up.

Trepkos contiuous butter maker catering for capacities up to 10 t. of butter per hour.

Trepkos new butter reworking system wich in its most advanced version, enable reworking from frozen state (-20oC).

See our offer

We encourage you to familiarize yourself with the offer of Trepko packaging machines